CCMCCM

CCM and moist maize silage

CCM and moist maize silage

CornCobMix and moist maize silage are an essential pillar of feeding for many farms. Due to the rapid availability of energy and nutrients (sugar, starch), these silages are considered to be particularly susceptible to reheating. There are always problems with yeast and mold. The effects on the feed value are serious, feed hygiene suffers and losses during feeding are inevitable. Even with the best silage management, this risk remains. Especially in the warmer months of the year, these silages tend to heat up and become mouldy. These problems can be reliably prevented by adding suitable silage additives such as CCM-Stabilizer and Lupro-Mix NA. Yeast and mold have no chance to grow.

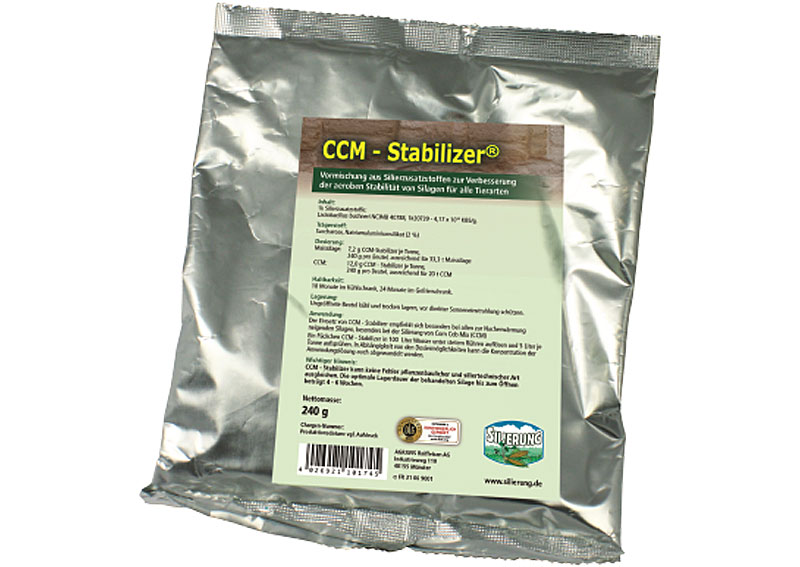

CCM–Stabilizer is a biological additive for improving the aerobic stability of Corn Cob Mix (CCM) after removal from the silo. The lactic acetic acid bacteria used in the CCM-Stabilizer were especially selected for the CCM field of application. They support the lactic acetic acid fermentation and enhance the stability of the CCM silage during air admission through their purposeful transformation into acetic acid. Losses caused by yeasts and moulds and the related heating up can be avoided.

CCM-Stabilizer has been tested in practice (table). It has been proved that the silage durability improves when exposed to the air.

CCM-Stabilizer is DLG-tested in group 2. The improvement of aerobic stability has been proven. It has been proved that the silage durability improves when exposed to the air.

The use of CCM-Stabilizer is especially recommended for CCM.

Dissolve one packet of CCM stabilizer into 100 litres of water stirring continuously and spray on 5 litres/ tonne fodder. Depending on dispensing possibilities, the concentration of the solution can vary. However, the amount must not fall below the recommended quantity of 5 litres per tonne CCM.

Careful examination has shown that our product, when used according to the directions for use, is suited for the recommended purposes. The optimal storage duration of the treated silage is 4 - 6 weeks before opening. If biological silage additives are used, then the ensilage and removal technique has to be very good. Plant cultivation errors and ensilage technique errors (e.g. compression and covering) cannot be compensated. We are liable for the consistent quality of the product, not for the risks of storage and use.

| Probename | 8. März 2001 | 8. Juni 2001 | 10. Juli 2001 |

|---|---|---|---|

| dry matter (%) | 61,4 | 61,0 | 60,1 |

| pH value | 4,3 | 4,2 | 4,3 |

| yeats (CFU/g) | < 500 | < 100 | < 100 |

| moulds (CFU/g) | < 20 | < 60 | 20 |

| lactic acid bacteria (CFU/g) | 4,4 x 108 | 2,7 x 107 | 1,2 x 108 |

| other bacteria (CFU/g) | < 400 | < 800 | < 400 |

Lupro-Mix NA is a buffered and highly effective mixture of propionic acid and formic acid. The natural lactic acid fermentation will be supported and active substances protect the ensilages safely from heating up and molding. The growth of yeast, molds and bacteria will be avoided and the hygiene of feed will be saved.

Lupro-Mix NA is DLG-proven. In group 1a,b, 2

The dosage is dependent of the field of application

Following application levels are recommended:

| DM-content | l / t |

| < 25 % | 4 |

| 25 – 35 % | 3 |

| > 35 % | 4 |

For total treatment of CCM and wet maize the dosage depends on storation time:

Surface and layer treatment

Per square metre 0,5 l Lupro- Mix NA (mixed with 2 l water)

layer thickness ca. 20 - 25 cm, treatment of 2 – 3 layers

Alternatively the total treatment of last loadings is possible.

Stabilization of TMR

3 l / to mixed ration

Stabilization on liquid feed

0,15 - 0,25 %

The usage of acids and their mixtures for conservation properties demands the HACCP – protocol.

There you can find the safety data sheet of Lupro-MIX NA

Additional information about the treatment of by products are here.

Propionic acid is a clear slightly yellow, strong smelling fluid. Its concentration is 99,5 % Propionic acid. This acid is able to inhibit moulds and yeasts, therefore improving the aerobic stability of treated silage.

Propionic acid is DLG – proven in group 2.

For all silages with heating up problems

The dosage is dependent on the field of application.

The following application levels are recommended:

| DM- content (%) | l/to |

| < 25 % | 4 |

| 25 - 35 % | 5 |

| > 35 % | 6 |

For total treatment of CCM and wet maize the dosage depends on storage time:

Surface and layer treatment

Per square metre 0,5 l Propionic acid (mixed with 2 l water)

layer thickness ca. 20 - 25 cm, treatment of 2 – 3 layers

Alternatively the complete treatment of last loads is possible.

Stabilization of TMR

3 l / to TMR

Stabilization of liquid feed

0,15 - 0,25 %

Additional information about the treatment of by products are here.

Propionic acid is corrosive. During application use protective gloves and safety glasses.

The usage of acids and their mixtures for conservation properties demands the HACCP – protocol.

There you can find the safety data sheet of Propionic acid.