Application SystemsApplication Systems

Application systems

Application systems

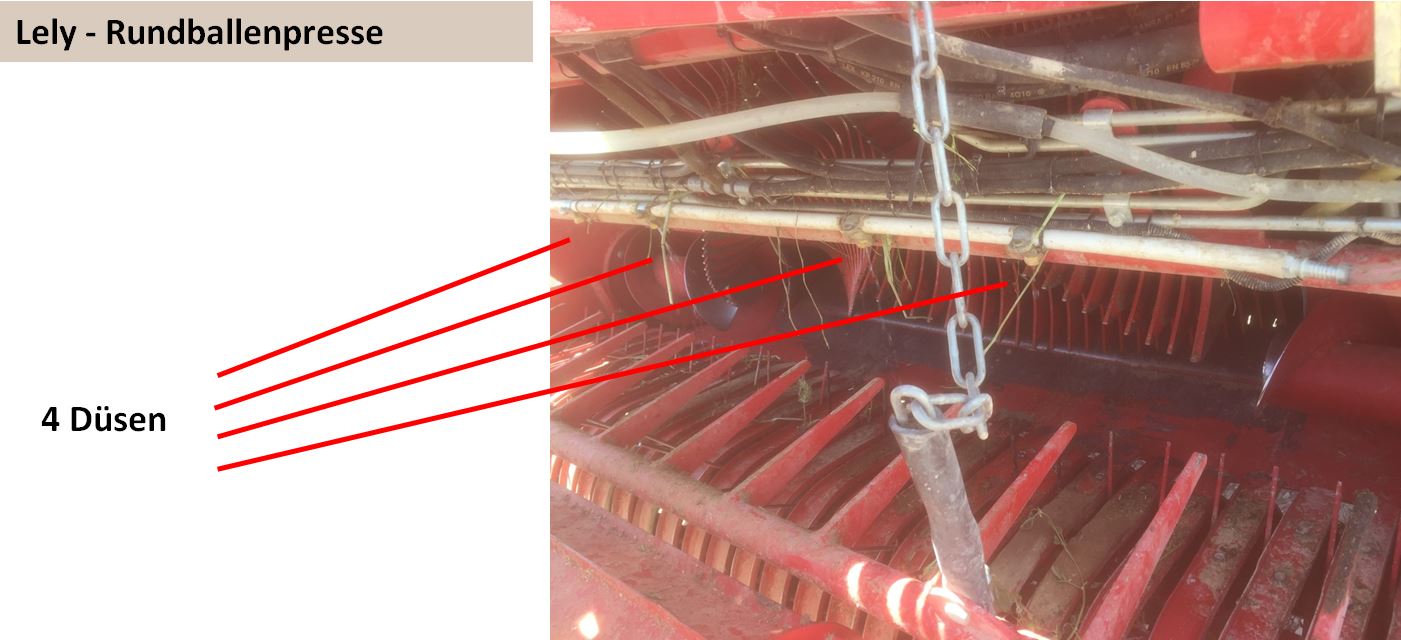

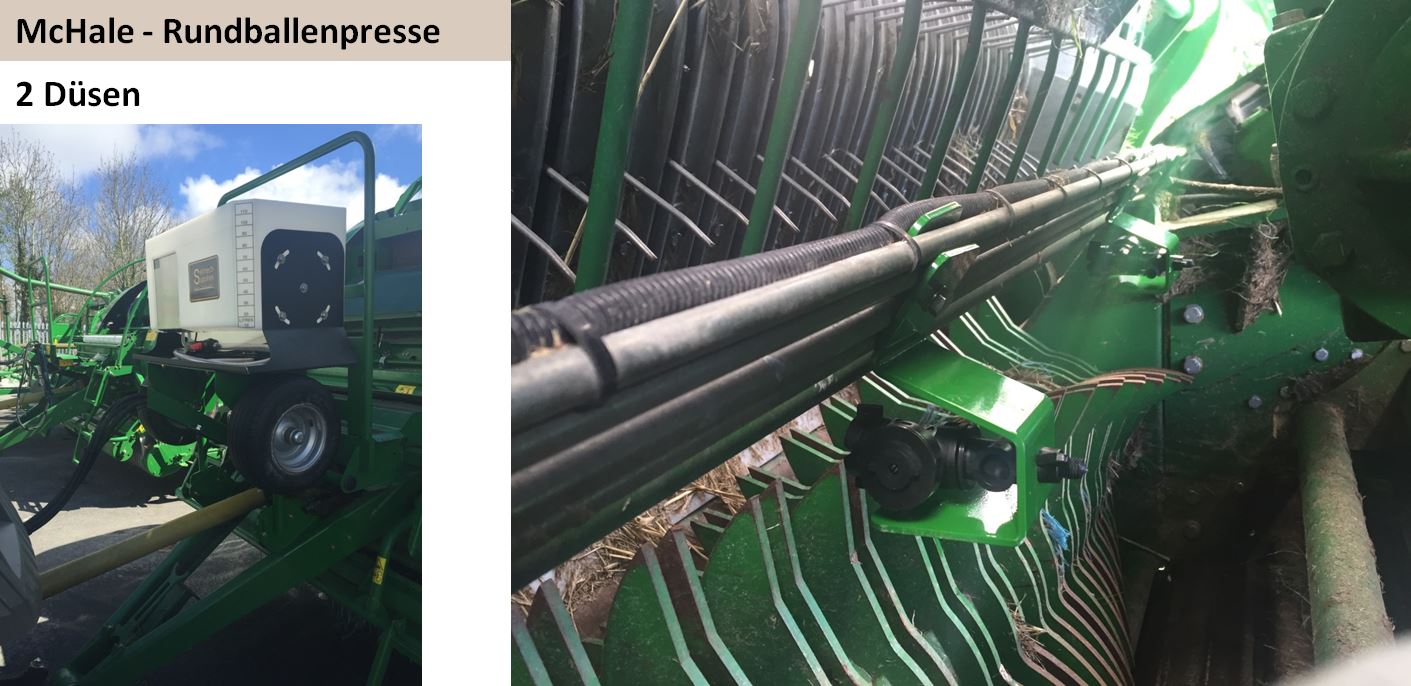

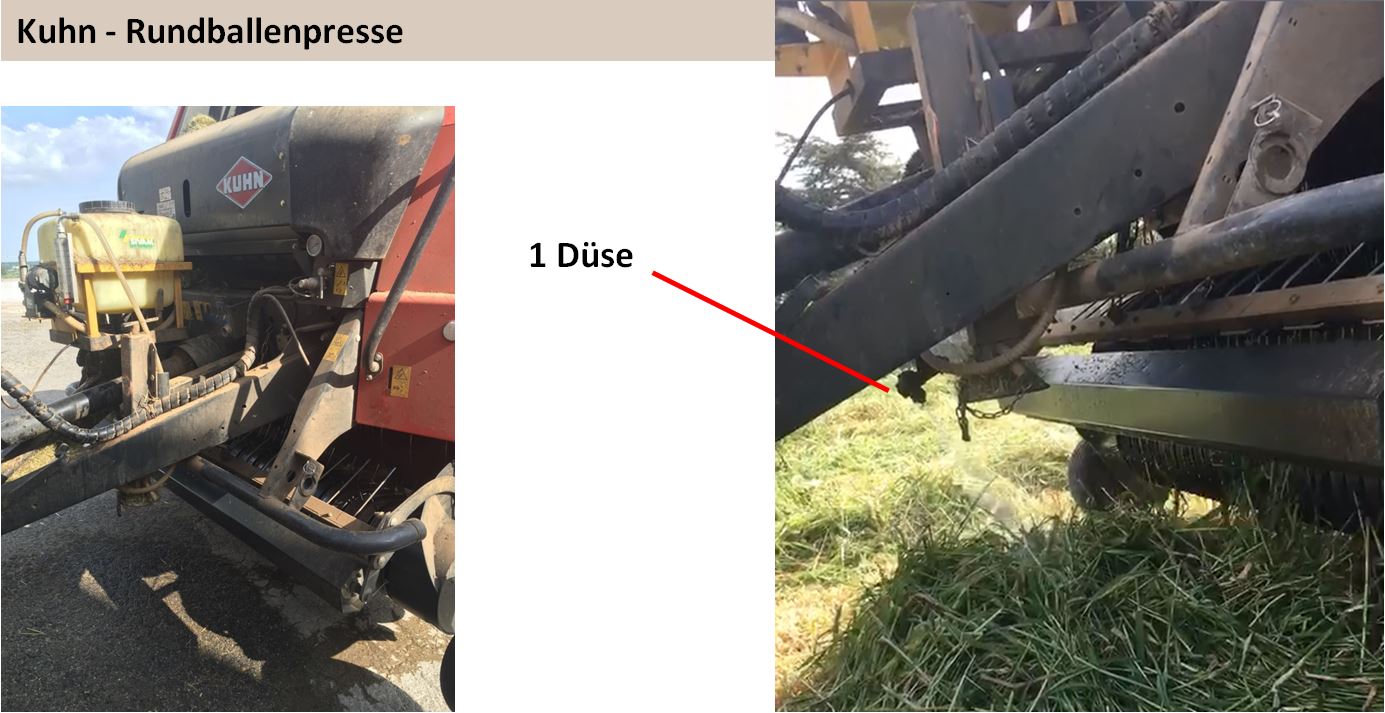

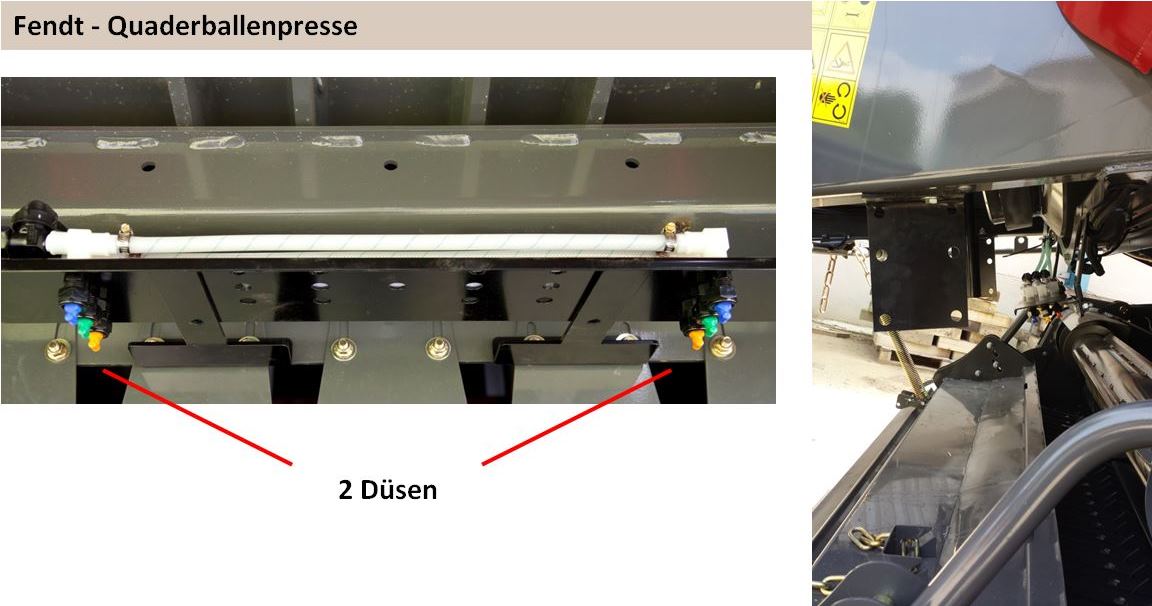

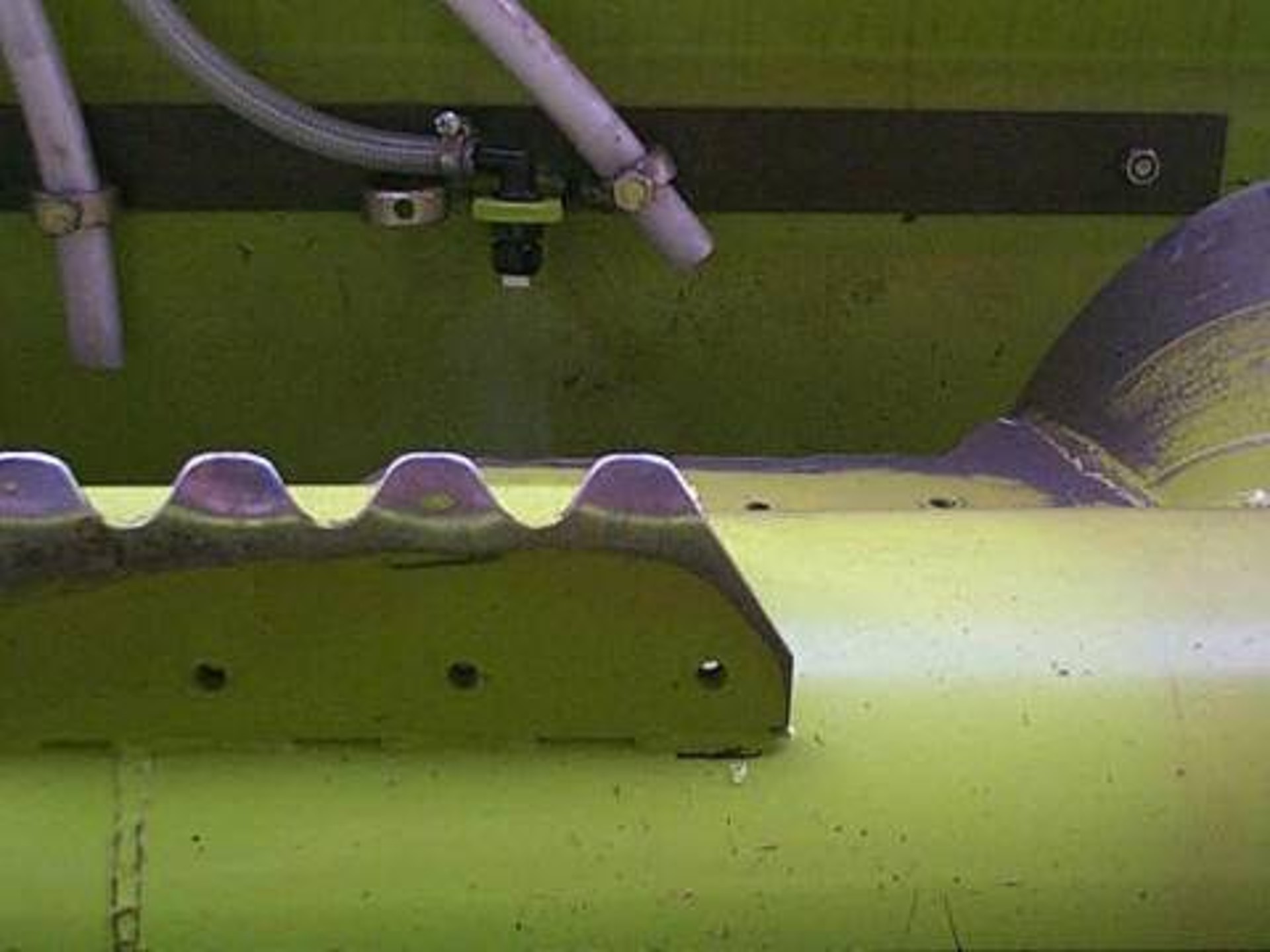

In addition to the right choice of silage additive, the equal dispersion of the product is extremely important. The application system must be able to apply the right dosage reliably in the forage. Because of their effectiveness and very good distribution, liquid application systems are more common in practice.

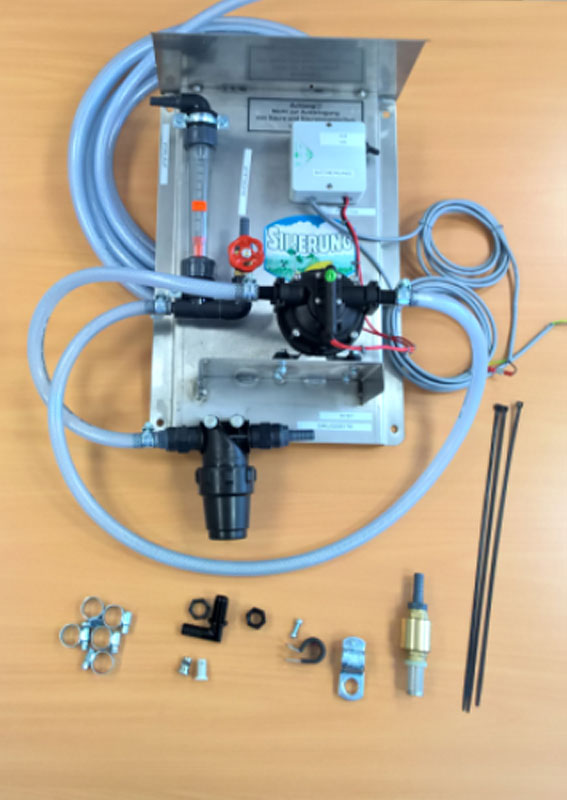

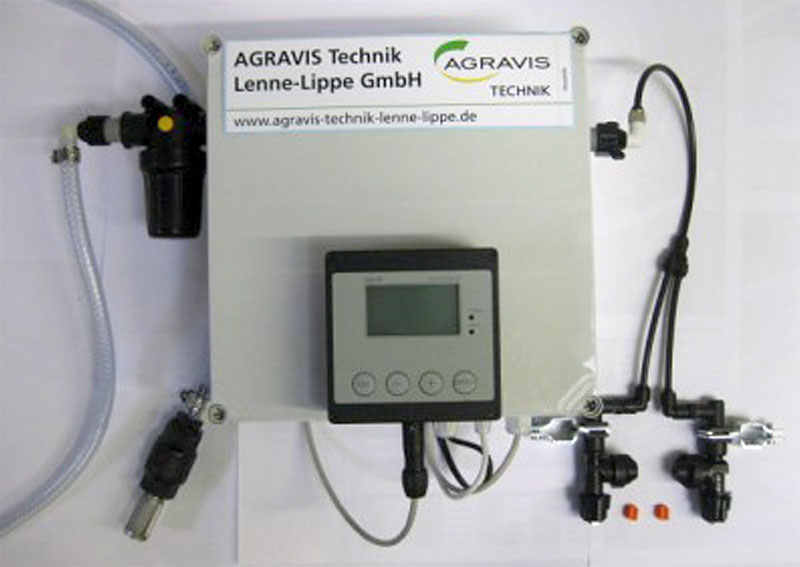

BioDos application systems are in-house developments of Agravis Raiffeisen AG. They are specially designed for all Raiffeisen silage additives. There are two different systems included. The “BioDos CL” can be used for all harvesting machinery. This system is able to apply biological additives in the same way as neutral salt solutions. The “BioDos ProfiLine” combines the standard system BioDos CL with a low volume dispensing attachment. It applies a low volume of dissolved additive to the liquid. The normal tank contains only the water, the additive is dissolved in a separate tank as a high concentrated solution. During the application process additive solution is mixed together with the water. The application systems will be complimented with the micro applicator “SilaTec”, which is able to apply low volumes of silage additive. This system will mainly be used on a field chopper.

basic device

price on request

additional device for BioDos CL

price on request

atomisation of organic ensilage agent

price on request

basic device

Price and other performance ranges on request

During harvesting work, the terminal should be installed in the driver's viewing area. The operating unit independently monitors the dosing system and you get visually and acoustically signals if a fault occurs. Then, the harvesting process should be interrupted to eliminate the fault. An error message is usually a lack of flow of silage.

Causes and helpful tips for removal and repair are listed in this chart.

You get more information from:

AGRAVIS Technik GmbH

Ludger Freßmann

AGRAVIS Technik Lenne-Lippe GmbH

Verkauf Ersatzteile

02581 . 6354-30